Horizontal Stainless Steel Powder Double Helical Ribbon Mixer/Ribbon Blender

Horizontal Stainless Steel Powder Double Helical Ribbon Mixer/Ribbon Blender

Ribbon Mixer

The High Grade Stainless Steel Double Helical Ribbon Blender is composed of container, screw paddles and transitional parts; the screw paddle are generally made into 1 layer or 3 layers, the outer screw converge is the material to the center front two sides, and the inner layer of screw conveys the material to the two sides from the center, so as to form convention mixing. The cubage can be made into rotundity, so the jacket can be played in reaction and drying.

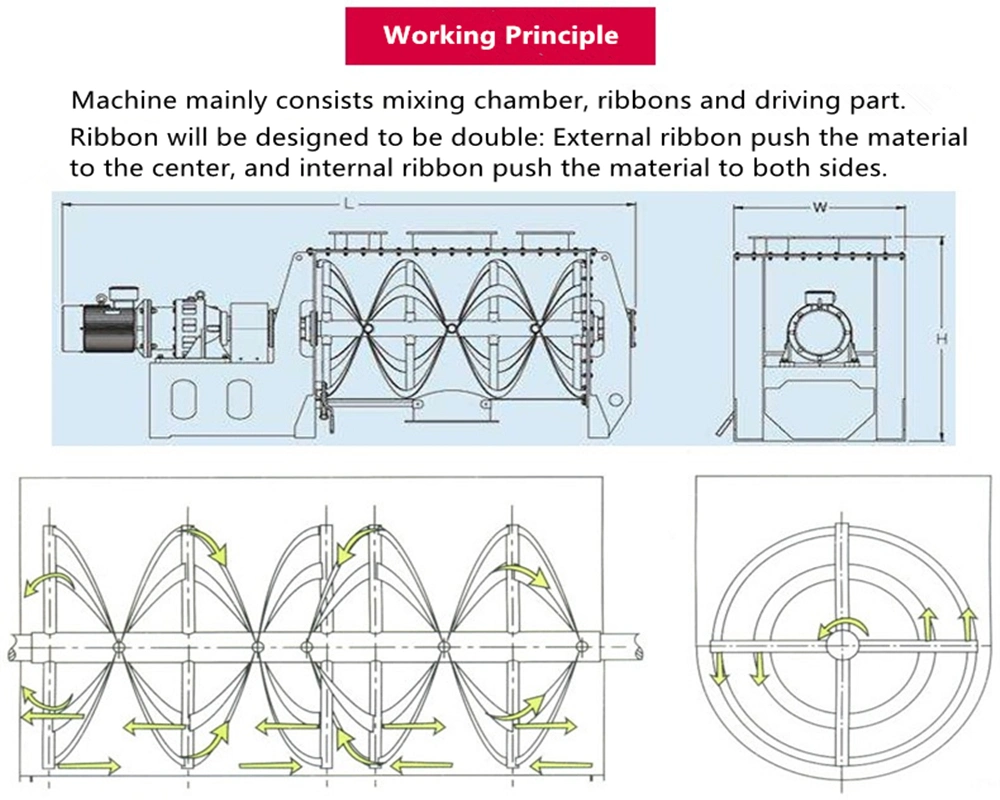

Double Helical Ribbon Blender Working Principle

The vortex outer ribbon combined with rotating direction drives material from two sides to the center, meanwhile inner ribbon drives material from center to two sides, and the high speed chopper blades could break and disperse the lumps and blocking.

Therefore horizontal double ribbon mixer with crushing chopper blades can especially meet the demands of various kinds of blending powdery materials which may easily gather together during the mixing process. Horizontal ribbon blender machine with high speed choppers is your best choice for mixing and blending powdery materials, liquid and powder.

Double helical ribbon mixer for powder mixing and liquid spray system is featured with shorter mixing time and better blending uniformity.

As the agitator rotates in the ribbon blender, the material is tumbled and carried radically around the inside of the blender. The pitch of the outer ribbon directs the material towards the discharge opening. The inner ribbon which also has an opposing pitch moves this material away from the discharge opening. This alternating movement creates very efficient mixing operation.

Exclusive Features of Ribbon Blender

- Available in working capacity of 5 liters – 25,000 liters.

- Available in all grades of stainless steel, carbon steel and special alloy steels.

- Ribbon agitator for center discharge.

- Designed for atmospheric operation.cking or Double Mechanical Seal as per requirements.

- Top cover depending on the length of the blender.

- Centrally located Flush bottom discharge valve.

- Stuffing boxes with easily disassembled housings. Pure Teflon gland packing provided.

- Stainless steel surfaces are polished to desired standards. All exterior non-stainless surfaces are painted with enamel paint.

- Squirrel Cage, Three Phase Induction Motors suitable for 415 Volts, 50 Hz.

- Worm Reduction Gearbox.

- Single Speed Drive.

- Double Helix Ribbon Blender is mounted on supports providing adequate discharge clearance.

Technical Parameters of Dry Powder Ribbon Blender Mixer

Technical Parameters of Dry Powder Ribbon Blender Mixer

| Model | Gross Volume approx. | Working Volume approx. | Power |

| RM-10 | 10 Liters | 5 Liters | 0.5 H.P. |

| RM-50 | 50 Liters | 20 Liters | 1 H.P. |

| RM-75 | 75 Liters | 50 Liters | 1 H.P. |

| RM-150 | 150 Liters | 100 Liters | 2 H.P. |

| RM-250 | 250 Liters | 150 Liters | 3 H.P. |

| RM-450 | 450 Liters | 300 Liters | 5 H.P. |

| RM-600 | 600 Liters | 450 Liters | 7.5 H.P. |

| RM-1100 | 1100 Liters | 750 Liters | 10 H.P. |

| RM-1500 | 1500 Liters | 1000 Liters | 12.5 H.P. |

| RM-2000 | 2000 Liters | 1250 Liters | 15 H.P. |

| RM-3000 | 3000 Liters | 1875 Liters | 20 H.P. |

| RM-5000 | 5000 Liters | 3000 Liters | 25 H.P. |

| RM-10000 | 10000 Liters | 6000 Liters | 40 H.P. |

GET THE BEST QUOTE